Product Categories

- Lawn Mowers

- CX550WJ Robot Control Gasoline Tyre Lawn Mowers

- CX550CB Robot Control Gasoline Crawler Lawn Mower

- CX800L Robot Control Gasoline Tyre Lawn Mowers

- CX1000L Robot Control Gasoline 22HP Lawn Mowers

- CX900T Robot Control Gasoline 22HP Crawler Lawn Mowers

- CX900T Plus Robot Control Gasoline 22HP Crawler Lawn Mowers

- CX500 Flail Robot Control Lawn Mower

- CX800 Flail Robot Control Lawn Mower

- Electric Lawn Mower

- Mini excavator

- Road Roller

- Excavator Parts

- Abrasives

- Agricultural Machinery

- Skid steering loader

- XCMG SECOND MACHINE

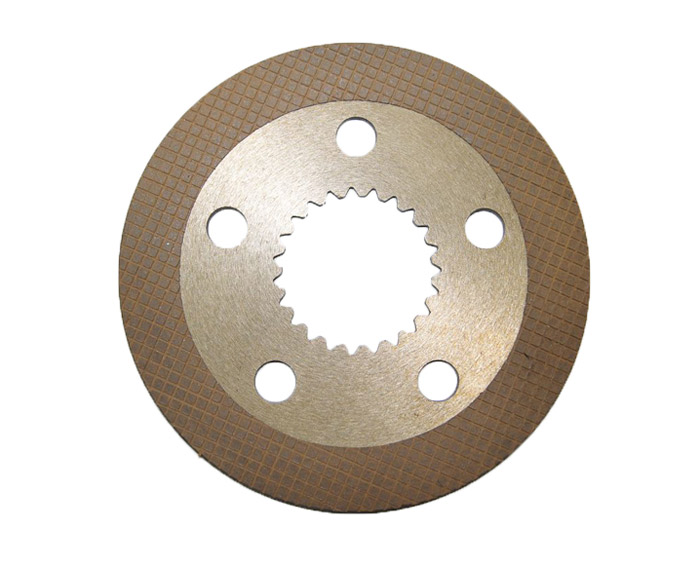

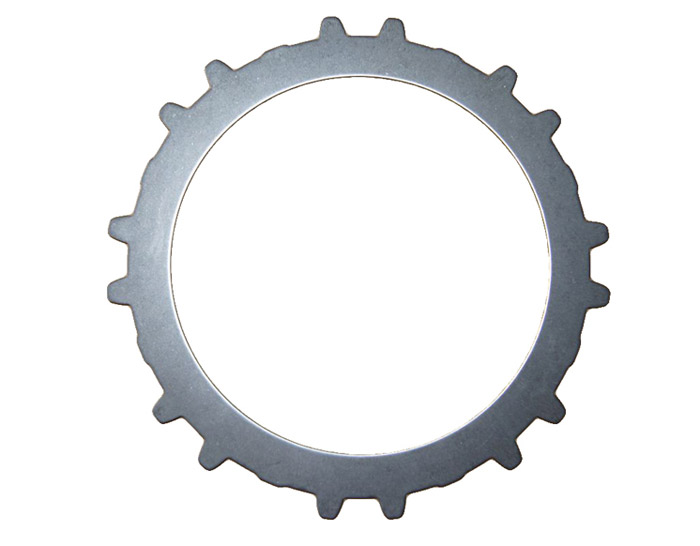

Advanced friction discs (Part 6Y5911) designed for modern biofuel-powered machinery in agriculture and construction. Features enzymatic coating and nanoceramic matrix to resist ethanol degradation and crop residue abrasion. Compatible with leading global equipment brands.

Biofuel-Optimized Friction Discs: Part 6Y5911

Engineered for next-generation biofuels, 6Y5911 friction discs withstand ethanol-blended diesel corrosion while maintaining performance in flooded fields and high-cellulose environments.

Compatibility Profile

-

Equipment Coverage:

Combine Harvesters | Biodiesel Excavators | Rice Paddy Tractors | Forestry Loaders | Biomass Handling Equipment -

Brand Fitment:

John Deere | Caterpillar | Komatsu | Claas | Kubota | CNH Industrial | AGCO | YTO

Technical Specifications

| Parameter | Specification |

|---|---|

| Core Material | Nanoceramic-infused cellulose |

| Biofuel Resistance | E100 Ethanol & B100 Biodiesel |

| Flood Tolerance | 72hr submersion capability |

| Abrasion Resistance | 8,000+ crop residue cycles |

| Dynamic Friction | μ=0.44±0.01 at 2.8MPa |

Performance Advantages

-

Enzyme-Activated Coating: Breaks down crop starch buildup during operation

-

pH-Balanced Formulation: Resists acidic soil corrosion (pH 3.5-9.0 range)

-

Hydrophobic Matrix: Prevents moisture absorption in rice paddies

-

Extended Service: 3x lifespan in sugarcane harvesters vs. standard discs

Critical Applications

-

Combine harvester transmission clutches

-

Biodiesel excavator final drives

-

Rice transplanter wet brake systems

-

Cotton picker PTO units

-

Biomass shredder engagement systems

Quality Assurance

-

Certifications: ISO 14224:2016, EU Stage V Compliance

-

Testing Protocol: 1,500hr biofuel immersion validation

-

Compliance: EPA Tier 4 Final, REACH Annex XVII

-

Traceability: DNA-tagged material batches

Contact Agritech Specialists via WhatsApp

Request Application Guides:

[+8615866053319]

→ Get crop-specific compatibility charts

→ Access flood resistance test videos

→ Discuss seasonal inventory planning

→ Obtain biofuel compatibility reports

Sector-Specific Advantages:

-

4-hour crop emergency response

-

Harvest season priority shipping

-

Starch-dissolving maintenance kits

-

DNA-based counterfeit protection