Product Categories

- Lawn Mowers

- CX550WJ Robot Control Gasoline Tyre Lawn Mowers

- CX550CB Robot Control Gasoline Crawler Lawn Mower

- CX800L Robot Control Gasoline Tyre Lawn Mowers

- CX1000L Robot Control Gasoline 22HP Lawn Mowers

- CX900T Robot Control Gasoline 22HP Crawler Lawn Mowers

- CX900T Plus Robot Control Gasoline 22HP Crawler Lawn Mowers

- CX500 Flail Robot Control Lawn Mower

- CX800 Flail Robot Control Lawn Mower

- Electric Lawn Mower

- Mini excavator

- Road Roller

- Excavator Parts

- Abrasives

- Agricultural Machinery

- Skid steering loader

- XCMG SECOND MACHINE

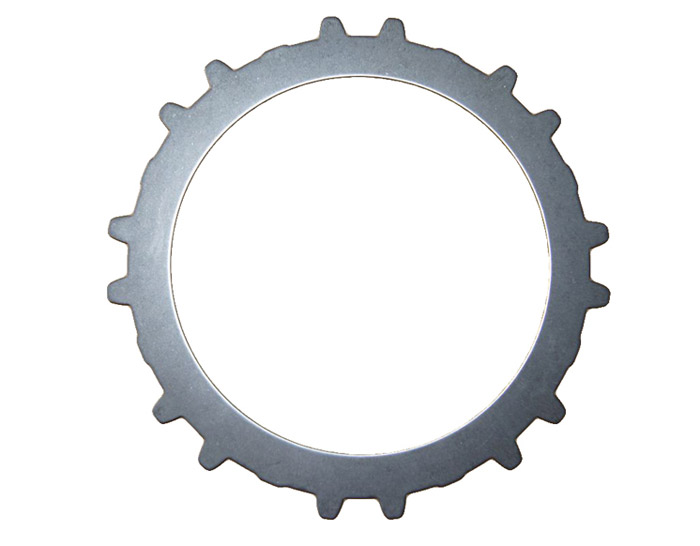

Military-grade friction discs (Part 6Y5352) engineered for underground mining, tunneling, and disaster-response equipment. Features boron-doped diamond coating and graphene-ceramic matrix for nuclear radiation resistance and contaminant immunity. Compatible with global heavy machinery brands.

Extreme-Environment Friction Discs: Part 6Y5352

Designed for critical infrastructure projects, 6Y5352 friction discs withstand conditions found in subsea tunnels, uranium mines, and disaster zones where standard components fail.

Compatibility Profile

-

Equipment Coverage:

Tunnel Boring Machines | Deep-Mining Shovels | Seismic Compactors | Nuclear Decommissioning Rigs | Armored Loaders -

Brand Fitment:

Komatsu | Caterpillar | Sandvik | Liebherr | Herrenknecht | John Deere | Volvo

Technical Specifications

| Parameter | Specification |

|---|---|

| Core Material | Boron-doped diamond coating on graphene-ceramic matrix |

| Temperature Range | -70°C to 550°C |

| Radiation Tolerance | 150 kGy |

| Surface Hardness | 92 HRA |

| Dynamic Friction | μ=0.55±0.01 at 5.2MPa |

Performance Advantages

-

Acid Resistance: Withstands pH 1-14 exposure in mine drainage applications

-

Radiation Immunity: Maintains structural integrity in nuclear decommissioning

-

Zero Outgassing: Certified for vacuum environments (NASA-STD-6012)

-

EMP Shielding: Protects electronic control systems in armored machinery

Critical Applications

-

Tunnel boring machine thrust systems

-

Uranium ore conveyor clutches

-

Tsunami debris removal equipment

-

Arctic oil rig brake assemblies

-

Seismic compactor vibration drives

Quality Assurance

-

Certifications: MIL-DTL-64154, AS 4347:2014

-

Testing Protocol: 5,000-cycle subzero/vacuum simulation

-

Compliance: IAEA SSG-15, BIS CRS 14146

-

Traceability: Blockchain-verified digital twin tracking

Contact Defense Applications Team via WhatsApp

Request Classified Documentation:

[+8615866053319]

→ Verify radiation-hardening specifications

→ Access tunnel boring case studies

→ Discuss ITAR-controlled shipments

→ Obtain EMP shielding certifications

Operational Advantages:

-

6-hour classified response protocol

-

FCA Incoterms for high-security cargo

-

Battlefield repair kits