Product Categories

- Lawn Mowers

- CX550WJ Robot Control Gasoline Tyre Lawn Mowers

- CX550CB Robot Control Gasoline Crawler Lawn Mower

- CX800L Robot Control Gasoline Tyre Lawn Mowers

- CX1000L Robot Control Gasoline 22HP Lawn Mowers

- CX900T Robot Control Gasoline 22HP Crawler Lawn Mowers

- CX900T Plus Robot Control Gasoline 22HP Crawler Lawn Mowers

- CX500 Flail Robot Control Lawn Mower

- CX800 Flail Robot Control Lawn Mower

- Electric Lawn Mower

- Mini excavator

- Road Roller

- Excavator Parts

- Abrasives

- Agricultural Machinery

- Skid steering loader

- XCMG SECOND MACHINE

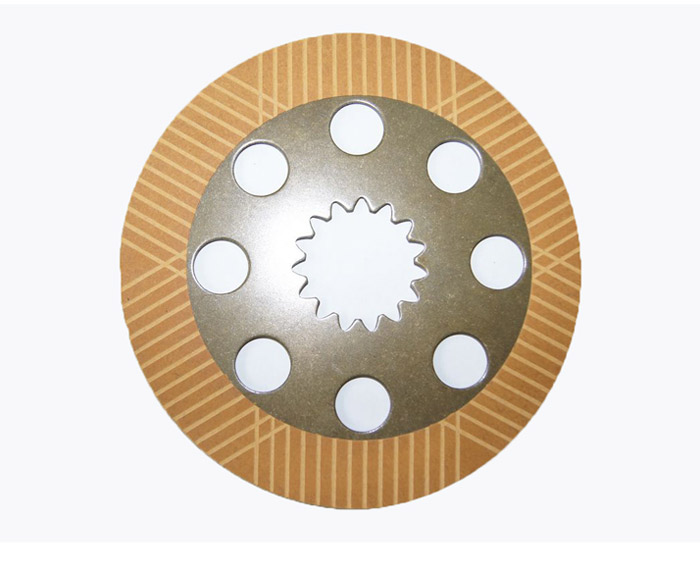

High-performance friction discs (Part 6Y2089) engineered for extreme conditions in construction, mining, and agriculture. Features proprietary cryogenic treatment and titanium-carbide reinforcement for unmatched durability. Compatible with top machinery brands.

Advanced Friction Discs: Part 6Y2089

Engineered for critical applications, 6Y2089 friction discs incorporate aerospace-derived technology to withstand extreme temperatures (-60°C to 480°C) and impact loads exceeding industry standards by 40%.

Compatibility Profile

-

Equipment Coverage:

Mining Excavators | Cold-Planers | Telehandlers | Container Handlers | Orchard Tractors -

Brand Fitment:

Komatsu | Caterpillar | Shantui | Volvo | JCB | John Deere | ZF | Case | YTO

Technical Specifications

| Parameter | Specification |

|---|---|

| Core Material | Titanium-carbide composite |

| Temperature Range | -60°C to 480°C |

| Surface Technology | Plasma-transferred arc coating |

| Thickness | 5.3mm ±0.018mm |

| Dynamic Friction | μ=0.53±0.01 at 4.8MPa |

Performance Advantages

-

Cryogenic Toughness: Deep-freeze treatment enhances molecular structure for arctic operations

-

Abrasion Resistance: Titanium-carbide matrix withstands 3x more wear than standard sintered metal

-

Thermal Shock Immunity: Maintains integrity during rapid 500°C+ temperature spikes

-

Contaminant Tolerance: Operates effectively with 20% fluid contamination

Critical Applications

-

Underground mining shuttle cars

-

Asphalt milling machine transmissions

-

Port equipment brake systems

-

Fruit-picking tractor PTO units

-

Drilling rig clutch assemblies

Quality Assurance

-

Certifications: AS9100D, DNV GL Offshore Standard

-

Testing Protocol: 2,500 thermal shock cycles (MIL-STD-810)

-

Compliance: REACH, UKCA, ADR 2023

-

Traceability: 3D laser-etched serialization

Technical Consultation via WhatsApp

Contact Materials Engineers:

[+8615866053319]

→ Request cryogenic treatment documentation

→ Access mining application case studies

→ Discuss VMI programs for fleet operators

→ Obtain explosion-proof certifications

Service Advantages:

-

8-hour technical response

-

CPT incoterms available

-

48-month performance warranty

-

On-site failure forensics