Product Categories

- Lawn Mowers

- CX550WJ Robot Control Gasoline Tyre Lawn Mowers

- CX550CB Robot Control Gasoline Crawler Lawn Mower

- CX800L Robot Control Gasoline Tyre Lawn Mowers

- CX1000L Robot Control Gasoline 22HP Lawn Mowers

- CX900T Robot Control Gasoline 22HP Crawler Lawn Mowers

- CX900T Plus Robot Control Gasoline 22HP Crawler Lawn Mowers

- CX500 Flail Robot Control Lawn Mower

- CX800 Flail Robot Control Lawn Mower

- Electric Lawn Mower

- Mini excavator

- Road Roller

- Excavator Parts

- Abrasives

- Agricultural Machinery

- Skid steering loader

- XCMG SECOND MACHINE

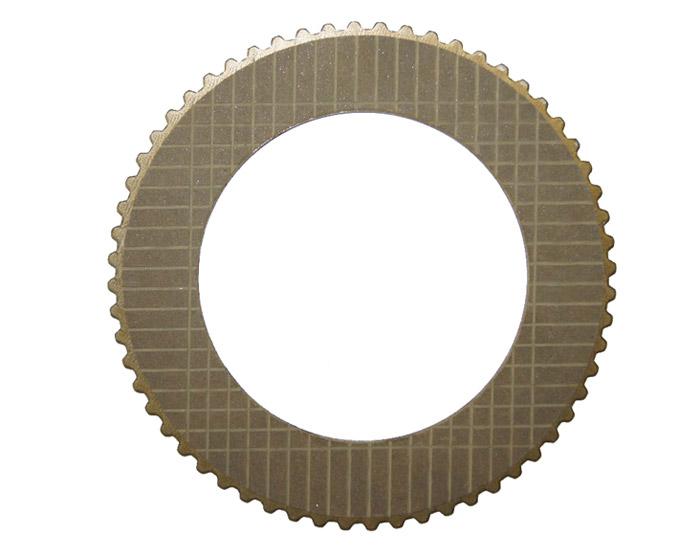

High-performance friction discs (Part 6Y2084) engineered to exceed OEM standards for construction, agricultural, and mining equipment. These discs ensure precise compatibility with excavators, compactors, loaders, and tractors from global brands.

Industrial Friction Discs: Part 6Y2084

Engineered for extreme-pressure applications, 6Y2084 friction discs deliver unmatched durability in high-torque transmission systems across mining, oilfield, and heavy construction operations.

Compatibility Profile

-

Equipment Coverage:

Hydraulic Excavators | Tandem Rollers | Skid-Steer Loaders | Forklifts | Row-Crop Tractors -

Brand Fitment:

Komatsu | Caterpillar | Shantui | Case | JCB | Volvo | John Deere | ZF | Kawasaki | YTO

Technical Specifications

| Parameter | Specification |

|---|---|

| Core Material | Molybdenum-reinforced steel |

| Temperature Range | -30°C to 470°C |

| Surface Technology | Micro-porous laser sintering |

| Thickness | 4.2mm ±0.015mm |

| Dynamic Friction | μ=0.52±0.01 at 4.5MPa |

Performance Advantages

-

Shock Load Resistance: Withstands 5X impact loads in demolition and mining applications

-

Thermal Recovery: Maintains friction coefficient after 200+ consecutive hard stops

-

Chemical Immunity: Resists drilling fluids, fertilizers, and hydraulic oil degradation

-

Extended Service: 50% longer lifespan in oilfield equipment validation tests

Critical Applications

-

Excavator final drive assemblies

-

Tractor power-shift transmissions

-

Loader differential brake systems

-

Oilfield pump drive units

-

Mining conveyor clutch systems

Quality Assurance

-

Certifications: API Q1, IATF 16949

-

Testing Protocol: 2,000-cycle pressure endurance validation

-

Compliance: REACH, UKCA, GOST-R

-

Traceability: RFID chip embedded tracking

Technical Support via WhatsApp

Contact Engineering Team:

[+8615866053319]

→ Verify fitment for specific models (e.g., CAT 336F, Komatsu PC450)

→ Request pressure endurance test videos

→ Discuss FCA terms for global shipments

→ Obtain API Q1 certification documents

Service Advantages:

-

10-minute response (business hours)

-

48-month performance warranty

-

Batch-specific material certificates

-

Customs clearance assistance