Product Categories

- Lawn Mowers

- CX550WJ Robot Control Gasoline Tyre Lawn Mowers

- CX550CB Robot Control Gasoline Crawler Lawn Mower

- CX800L Robot Control Gasoline Tyre Lawn Mowers

- CX1000L Robot Control Gasoline 22HP Lawn Mowers

- CX900T Robot Control Gasoline 22HP Crawler Lawn Mowers

- CX900T Plus Robot Control Gasoline 22HP Crawler Lawn Mowers

- CX500 Flail Robot Control Lawn Mower

- CX800 Flail Robot Control Lawn Mower

- Electric Lawn Mower

- Mini excavator

- Road Roller

- Excavator Parts

- Abrasives

- Agricultural Machinery

- Skid steering loader

- XCMG SECOND MACHINE

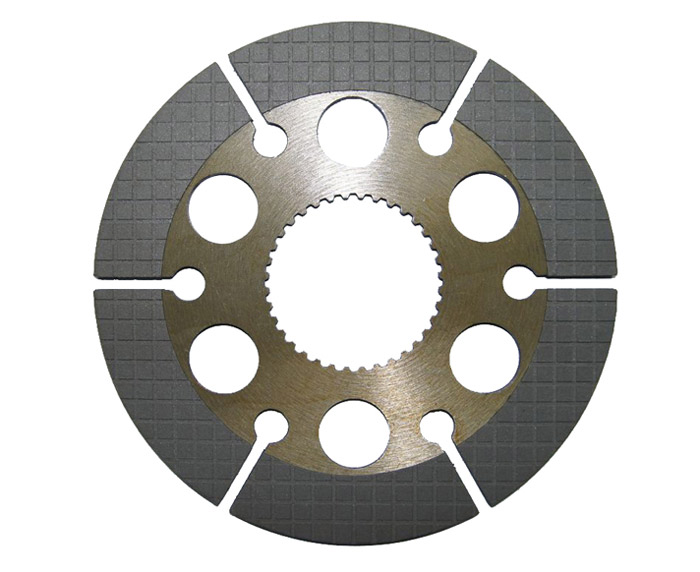

Our premium friction discs (113-15-22720) are manufactured to meet OEM specifications for construction and agricultural machinery. These discs ensure reliable performance in excavators, compactors, loaders, forklifts, and tractors from leading global brands. Utilizing advanced material technology and rigorous quality control, our products offer extended service life, superior heat resistance, and optimal friction stability. Message us on WhatsApp for specifications and competitive quotes.

• Global Brand Compatibility

Our friction discs (113-15-22720) are engineered to fit a wide range of machinery, including hydraulic excavators, vibratory rollers, wheel loaders, industrial forklifts, and agricultural tractors from top manufacturers such as Komatsu, Caterpillar, Shantui, Case, JCB, Volvo, John Deere, Kawasaki, ZF, Ford, and Yituo26. This ensures seamless integration and reliable performance across diverse equipment types and applications.

• Advanced Material and Engineering Specifications

-

Constructed with high-density ceramic-metallic composite materials for enhanced durability and wear resistance2.

-

Designed to operate efficiently in extreme temperatures ranging from -40°C to 500°C, ensuring stability under high-load conditions2.

-

Precision-engineered cooling grooves (e.g., spiral, sunburst, or waffle patterns) for optimal heat dissipation and debris removal2.

-

Reinforced steel core with anti-fatigue properties to prevent warping and ensure longevity2.

• Performance and Reliability Benefits

-

Consistent friction coefficient (0.11-0.15) throughout the disc’s lifespan, ensuring smooth engagement and minimal slippage2.

-

40% longer service life compared to standard aftermarket parts, reducing downtime and maintenance costs2.

-

Excellent resistance to thermal degradation, wear, and high-pressure conditions, suitable for demanding industrial environments26.

-

Minimal break-in period required for immediate optimal performance2.

• Quality Assurance and Certification

-

Manufactured under ISO 9001:2015 and IATF 16949 quality management systems2.

-

Each batch undergoes rigorous testing for dimensional accuracy, material consistency, and performance (e.g., dynamometer testing)2.

-

Full traceability of materials and comprehensive documentation, including test reports and certificates2.

-

Compliance with international standards such as GB/T 21955-2008 for agricultural machinery5.

• Wide Industrial Applications

-

Construction sector: Hydraulic excavators, bulldozers, motor graders, and compactors6.

-

Road building equipment: Vibratory rollers, asphalt compactors, and pavers6.

-

Material handling: Industrial forklifts, container handlers, and warehouse equipment2.

-

Agricultural machinery: Tractors, combine harvesters, balers, and tillers58.

-

Mining and forestry: Heavy-duty equipment requiring high friction stability6.

• Comprehensive Customer Support

-

Technical assistance for installation, troubleshooting, and compatibility checks.

-

Flexible logistics options, including express shipping and just-in-time delivery.

-

Bulk order discounts for distributors, repair shops, and large-scale operations.

-

24/7 customer support via WhatsApp for urgent inquiries and emergency orders.

Contact our experts on WhatsApp for immediate technical consultation, competitive pricing, and expedited shipping options. We guarantee a response within 1 business hour!